Innovative container systems since 1740.

THE COMPANY

Since February 2024, the local management team has taken over UCS and is now running the company independently and with respect for its long history .

The strategy is focused on special containers and container systems, innovation and service. So that we pursue the goal of offering our customers solutions that make their value creation more efficient and thus and thus not only enable sustainable production, but also significantly support the business model.

We consider the entire material flow from delivery, filling and decanting or dosing, cleaning and storage through to the transportation of our customers’ bulk materials and liquid products.

Sustainability, environmental protection and occupational health and safety guide our actions. This is shown not only by our solutions and our stainless steel products, but also the way we act and think during the solution implementation.

OUR CORE COMPETENCIES

As a leading provider of container systems, UCON places sustainability at the heart of its product development.

With a high-quality, fully recyclable stainless steel IBC, UCS Container Systems is driving forward the development of the circular economy as described in the UN’s 2030 Agenda for Sustainable Development. This focus on sustainable innovation goes hand in hand with our efforts to guarantee the highest quality and safety. The stainless steel IBC not only offers a safe solution for workers and the environment, but also enables a reliable production process for the customer. The high ease of cleaning prevents cross-contamination and ensures the highest quality and safety of our customers’ products.

We offer solutions for various industries:

Expertise in emptying, dosing and mixing bulk materials.

UCON Container System.

Innovative – Efficient – Sustainable

Our solutions cover your entire production process. All our products can be customised to your individual needs and equipped with different interfaces so that they can be seamlessly integrated into your production.

Transport – UCON offers the most comprehensive portfolio of IBC containers and systems for the transport of bulk goods in the food or chemical industry as well as in the coating and pharmaceutical industry.

Storage – With a particular focus on maximising safety, our containers are the ideal choice for storing everything from harmless materials to hazardous goods.

Mixing – Our bulk containers can be used to homogenise your products in conjunction with a tumble mixer, for example. This means that your products always remain in the same container from filling to dosing. This minimises the amount of cleaning required and prevents cross-contamination.

Emptying – Our fully automatic dosing and emptying stations ensure optimum leak-tightness and minimise the risk of product contamination. Our containers are designed to meet the highest quality standards and fulfil the most demanding requirements of our customers. Our solutions can be UN approved, ATEX certified and customised for GMP. Our container systems ultimately offer a modular solution that grows with your business.

Customised solutions – Since you are the best experts in your field of work and standardised solutions cannot always be the answer to all requirements, we work hand in hand with you towards our most ambitious goal: Your satisfaction. Whether fully automatic, semi-automatic or manual solutions: a UCON team of experts is on hand to help you make the right decision and find a customised solution. This gives you a system with guaranteed maximum safety, hygiene, erfection and a long service life.

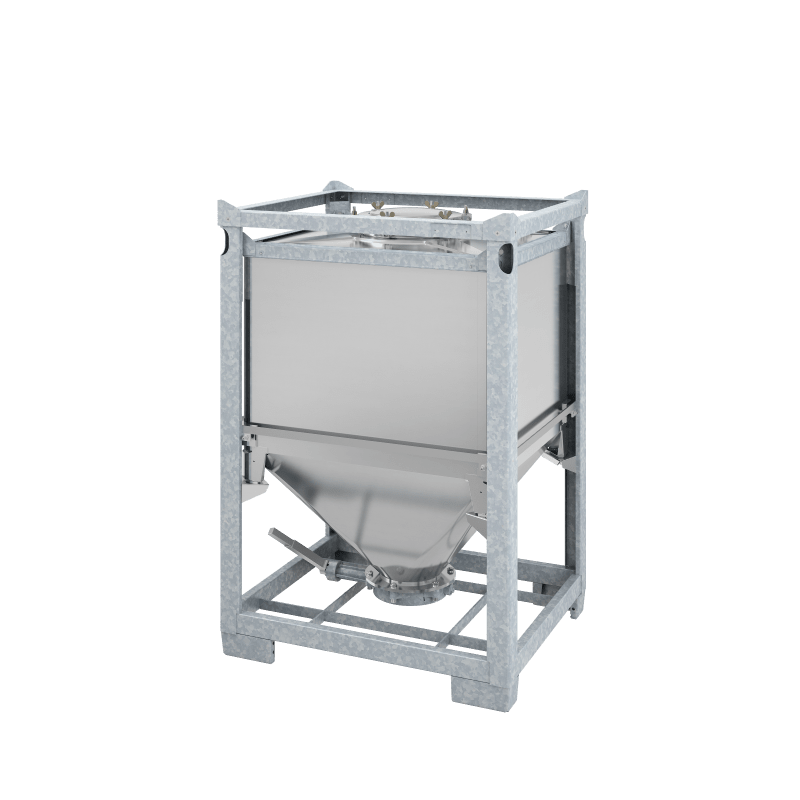

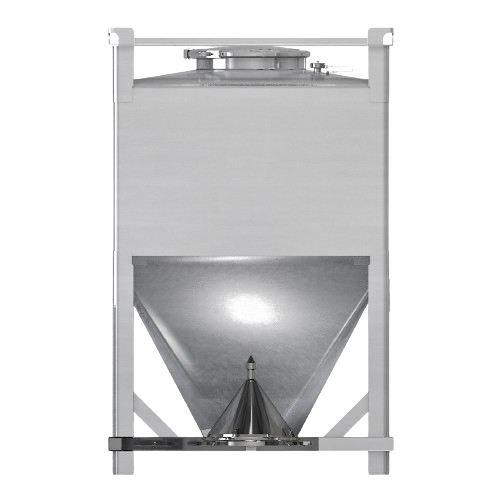

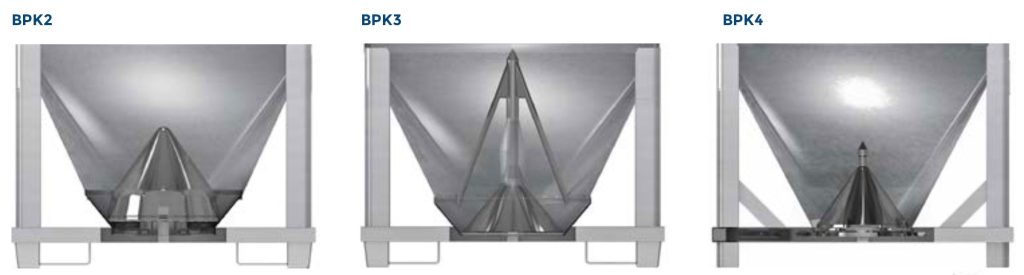

Our BPK container systems with conical closure

Discharging and dosing via conical closure, the best solution for poorly flowing and bridging bulk solids.

Our conical closure systems can be customised to your specific needs and requirements to avoid bridging or void formation. We design our container systems to the highest safety standards, for optimum hygiene and for modular and easy-to-operate applications. They guarantee complete emptying with simultaneous flow control via fully automated processes.

via fully automatic processes. Our different container systems are variable solutions that adapt to the bulk material according to your needs, whether it is free-flowing, bridging or compacting products or whether you need to keep dust formation under control at all times. Our technical sales team will be happy to help you select the optimum solution for you.

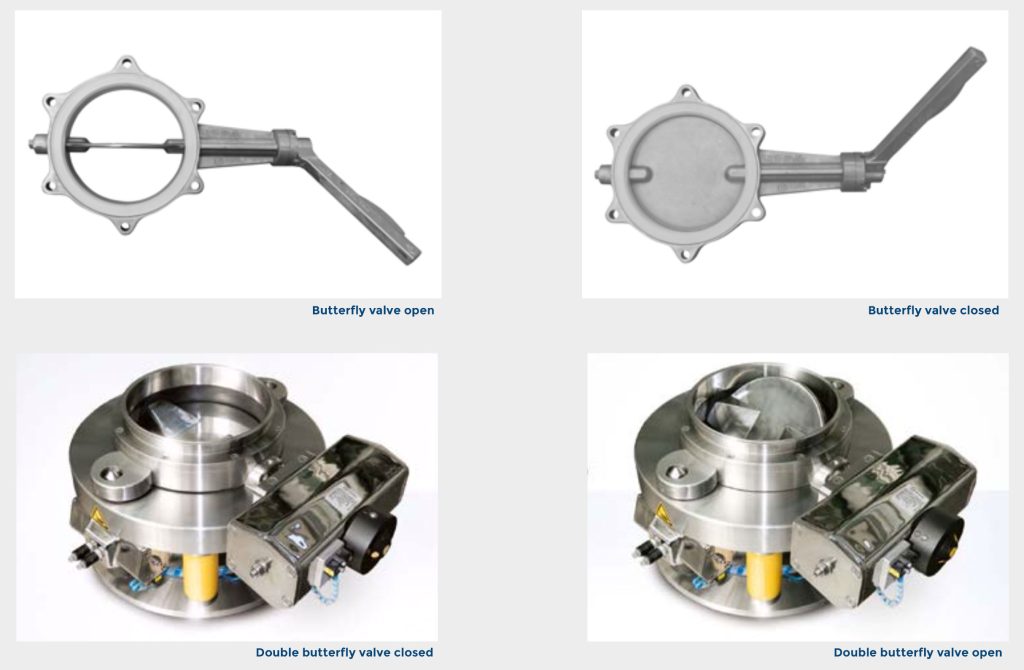

Our BP & BPO container systems with flap closure

Emptying and dosing via dosing and vibrating flaps, the best solution for minimising dosing tolerances.

Our dosing flap systems are the ideal solution for fully automatic and semi-automatic operation. The dosing double flap system is part of the UCON bulk container systems for the most demanding pharmaceutical and chemical requirements and operating conditions. It is characterised by the hermetically sealed and contamination-free transfer between container and emptying unit without exposure to dust. The main applications include use with hazardous bulk goods or contamination-free handling under clean room conditions, for example in the pharmaceutical and chemical industries.

Certifications

The increasing requirements for employee and environmental protection as well as industry standards and safety regulations, including

- CE approval

- ATEX approval

- UN approval

- FDA conformity

- CSA certification

are fully taken into account, as are industry-specific requirements such as non-ferrous metal for the systems.

We are at your disposal for further information.

PRODUCTS

IBCs FOR LIQUIDS AND BULK MATERIAL

SERVICES

After Sales

UCON Container System GmbH attaches particular importance to comprehensive after-sales service and maintenance services. We specialize in IBC systems and serve various industries such as chemicals, pharmaceuticals and food. Our international presence enables us to support customers worldwide.

IBCs with approval are subject to 2.5 and 5-year inspections, which we can efficiently combine with repairs.

Effective spare parts management is an integral part of our service offering.

Our aim is to ensure the high availability of our systems, as we see continuous operational readiness as crucial to the success of our customers.

NEWS

Stay informed!

- 21. February 2024

How Thielmann Ucon became Ucon again

The change of name from Thielmann to Ucon was reported in the Lahrer Zeitung on February 20, 2024. -> ... - 20. February 2024

Why Ucon is independent again.

On February 20, 2024, an article appeared on Baden-Online about the future of the company. -> Click here to ...

HISTORY OF UCON CONTAINER SYSTEM GMBH

UCON has been supplying innovative container systems since 1740.

There is a constant need for container solutions in a wide variety of industries around the world. And it is always important to find the right partner with the best container solutions that the customer can rely on.

With over 280 years of experience, we are the world’s leading manufacturer of stainless steel containers and have the best container expertise that our customers can use with confidence.

-

2024

Igor Ferlan and Ulrich Lauster are managing directors of the now independent company Ucon Container System GmbH in Hausach.

-

2015

Thielmann Ucon celebrates 275 years.

-

2013

UCON AG decides in favour of the Hausach site. The Haiger site is closed.

-

1999

The Teka Group takes over through its subsidiary Thielmann AG, the company now operates under the name Ucon AG Containersysteme KG with the additional site in Haiger.

-

1986

Umformtechnik Hausach GmbH is founded with the managing directors Hans-Jürgen Sokol and Frierich-Karl Simon.

-

1970

Acquisition by the Thyssen Group.

-

1960

Start of series production of small containers.

-

1950

Start of container and tank construction.

-

1938

Mannesmann takes over the plant.

-

1900

The Bühler entrepreneurs Wolf Netter and Solomon Jacobi buy the factory. Start of the upswing to become a renowned industrial company.

-

1888

Conversion of the company into a plate rolling mill.

-

1740

Foundation of the company by the Litschgi brothers.

Visit us at these trade fairs!

CONTACT

How can we help you?

UCON Container System GmbH

Gustav-Rivinius-Platz 2

77756 Hausach

Germany

Tel: +49 7831 7727-0

Fax: +49 7831 77209

E-Mail: info@uconcs.com