CHOOSING THE BEST GAS TO TAP YOUR BEVERAGES

Carbonation, which affects the taste of beverages, must be monitored closely to ensure that the organoleptic properties of the foodstuffs remain unaltered or are altered only as desired by the producer.

THIELMANN can help your brewery grow with our ever-expanding range of keg servicing programs including keg maintenance, repairs, customization services, tagging services, cleaning, inspections, testing, and re-branding. Taking the hard work out of servicing your keg fleet, allowing you to focus on brewing.

Our experts have a wealth of experience in helping breweries re-purpose used keg fleets with our customizable re-branding services, which can be tailored to your specific needs, to repair, refurbish, and fully re-brand your used keg fleet.

Kegs can be damaged in many ways throughout the supply chain. THIELMANN offers a bespoke servicing and repair program that ensures your keg fleet remains in optimal condition, increasing the reliability and durability of your initial investment – saving you money by removing the need for equipment replacement.

Stainless steel kegs require regular servicing in order to remain fit for their filling, storage, packaging, and transportation purposes throughout your supply chain. Our stringent processes ensure that every keg is serviced to the highest possible standards – keeping your brewery operation running smoothly.

Our cutting-edge lean processes mean as a business we can offer our services at excellent value, making us the number one choice for brewers, of any size, throughout the world.

FULL SERVICE AND REPAIR PROGRAM

MAKE YOUR FLEET LOOK UNIQUE

We provide different branding solutions for your new and/or used kegs. From standard lettering to full logo printing, your kegs will stand out from the crowd.

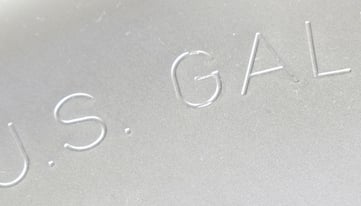

Take pride in seeing your branding embossed or engraved into the chimes of our impeccably manufactured stainless-steel kegs. From standard characters to full logo design, embossing your logo will outstand your keg from the rest.

With our long-lasting stickers, you have an easy branding option for your kegs which guarantees the possibility of rebranding in case you need it in the future. Our stickers are proved to work under heavy-duty environments (heat, sun, washing machines,…).

Create a consistent branding experience by having your brand’s logo screen-printed onto the stainless steel body of your THIELMANN keg. Just send us your logo, we accept a great variety of formats, and tell us the RAL or Pantone color you prefer. Your branding consistent across all channels.

A great solution for identification purposes (matrix codes, complex logistics, tracking…) and for small logo requirements. You can have laser-printed markings added to your THIELMANN kegs. Tell us your requirements.

With THIELMANN Kegs, you can also add color bands to customize your kegs. Ideal for easy identification, this option provides your fleet with a unified color scheme. You can choose your preferred colors in RAL or Pantone system.

Engraving provides an alternative to embossing for longer text requirements such as technical details, specs, or any other information. It represents a long-lasting solution to customize your kegs.

Control and manage your fleet with an easy-to-use, efficient, and cost-effective system.

A wide range of solutions for complex logistics systems is available.

Tracking solutions wich will allow you to:

THIELMANN has partnered with ROTECH to provide an essential hygiene and quality monitoring tool for every brewery with a keg filling line, large or small.

It comprises a brewery standard keg fitted with sensors and a data logger, with custom software to check every cycle of keg washing, disinfection, filling. You can ensure washing and disinfection are exacting, and gassing and filling are fully efficient.

Highlights include:

ROTECH/THIELMANN smart kegs ensure your product meets the highest standards – no doubts, no questions - a complete picture and record of your keg line performance.

As the worldwide leader in stainless steel container solutions, THIELMANN has accumulated significant expertise across a wide range of industries over many years. Our experts regularly compile educational material and analyses such as our Whitepapers and Case Studies, which are an excellent way to share in our knowledge and expertise and to find out more about our industry, product and application-specific insights and experience. We invite you to peruse our informative material and welcome any questions or enquiries you may have.

Carbonation, which affects the taste of beverages, must be monitored closely to ensure that the organoleptic properties of the foodstuffs remain unaltered or are altered only as desired by the producer.

A keg fleet is only as strong as its weakest keg.

There will always be a need for container solutions for a variety of industries around the world. And there will always be a need to find the right partner, with the best and most reliable container solutions for every eventuality.

2026 © THIELMANN - The Container Company. All rights reserved.